When people hear “Tesla,” they often think of electric cars, Elon Musk, or groundbreaking technological innovations, however, one fascinating fact about the company that only a few people discuss is its incredible mass flux, Tesla Mass Flux, the total amount of complex manufactured goods the company moves, has reached approximately 4 million tons. This number might sound hard to grasp, but it’s a testament to the scale of Tesla’s operations and its impact on the global market.

What Does 4 Million Tons of Manufactured Goods Mean?

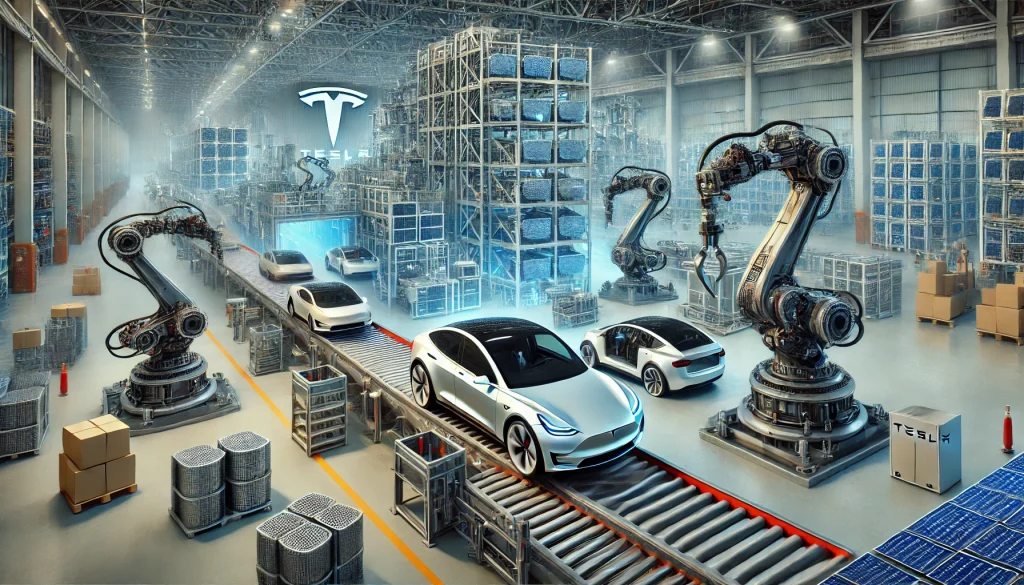

Simply put, the mass flux of 4 million tons refers to the weight of all the goods Tesla produces and ships globally yearly. These goods include electric cars, solar panels, batteries, and other energy products. Imagine the sheer volume of parts, materials, and finished products moving through Tesla’s factories to achieve this figure.

It’s also important to consider that these goods are more complex products. Tesla’s electric vehicles (EVs) are made from various materials, from high-grade metals and plastics to cutting-edge electronic components. Every car, battery, and energy solution Tesla produces is a complex combination of precision engineering and advanced materials. This makes the mass flux of 4 million tons all the more impressive, as it represents not just the volume of goods but their complexity.

Why Is Tesla’s Mass Flux So High?

There are several reasons why Tesla’s mass flux is so large. The company’s growth in recent years has been astronomical. With more factories being built worldwide, especially the famous Gigafactories, Tesla is producing more cars, batteries, and solar products than ever. This is all part of its mission to accelerate the world’s transition to sustainable energy. The faster Tesla can produce and ship its products, the faster it can impact reducing carbon emissions globally.

The popularity of Tesla’s electric vehicles is another key factor. As more people switch to electric cars, the demand for Tesla’s products keeps rising. The company has become one of the top automakers in the world, producing hundreds of thousands of cars every year. Each of these cars requires significant raw materials, parts, and assembly, all contributing to the massive 4 million tons.

Tesla’s Global Impact on Manufacturing

Tesla’s mass flux represents the company’s internal operations and broader influence on the global manufacturing industry. Tesla has revolutionized how electric vehicles and energy solutions are built, focusing on efficiency and innovation.

For example, the company’s gigafactories are designed to streamline the production process, making large quantities of goods faster and more efficient. These factories are also located strategically worldwide, allowing Tesla to meet global demand without long shipping times or delays. As a result, Tesla has set a new standard for large-scale manufacturing in the modern world.

The Environmental Impact of Moving 4 Million Tons of Goods

When discussing Tesla, it’s essential to consider the environmental angle. The company’s core mission is to help reduce the world’s reliance on fossil fuels and lower carbon emissions. However, producing and shipping 4 million tons of goods yearly requires energy and resources.

Tesla is aware of this challenge and has taken steps to minimize the environmental impact of its manufacturing processes. The Gigafactories, for example, are powered by renewable energy, such as solar and wind, helping to reduce the carbon footprint associated with production. Additionally, Tesla’s focus on sustainability extends to its supply chain, which aims to responsibly source materials and reduce waste.

A Complex Supply Chain Behind the Numbers

Behind Tesla’s massive production numbers lies a highly intricate supply chain. Tesla doesn’t just build cars, it also needs to manage the flow of thousands of parts and components from suppliers worldwide. These parts include everything from lithium-ion batteries to microchips, all necessary for producing Tesla’s electric vehicles and energy products.

Managing such a complex supply chain is a challenging task. Tesla has invested heavily in ensuring its suppliers can keep up with demand, often working closely with them to improve efficiency and reduce bottlenecks. The company has also explored vertical integration, which involves more of the manufacturing process in-house. This helps Tesla maintain control over the quality and availability of critical components.

Challenges of Meeting Global Demand

Despite Tesla’s remarkable achievements, meeting the global demand for its products has sometimes been challenging sailing. The company has faced various challenges, including supply chain disruptions, shortages of key materials, and logistical hurdles.

For instance, the global semiconductor shortage has affected many industries in recent years and has impacted Tesla’s ability to produce its cars at the desired rate. While Tesla managed to navigate these issues better than some competitors, it highlighted the fragility of global supply chains and the challenges of scaling production to meet increasing demand.

What Does the Future Hold for Tesla’s Mass Flux?

As Tesla continues to expand its operations, its mass flux will likely grow even larger. With new Gigafactories under construction and plans to increase production of electric vehicles and energy products, the company’s footprint in the global market is sets to increase.

Introducing new products like the long-awaited Cybertruck and the Tesla Semi will also contribute to this growth. Both vehicles are expect to be in high demand, and their production will add significantly to Tesla’s overall output.

Additionally, Tesla’s push into new markets, such as energy storage and renewable energy generation, will further boost its mass flux. The company’s batteries and solar products are becoming increasingly popular as more individuals and businesses look for ways to reduce their reliance on traditional energy sources.

Conclusion

Tesla’s mass flux of approximately 4 million tons of complex manufactured goods is a staggering figure that highlights the company’s rapid growth and global influence. It’s a testament to Tesla’s manufacturing processes’ efficiency and ability to meet the rising demand for electric vehicles and sustainable energy solutions.

While challenges are ahead, including supply chain disruptions and the need to further reduce its operations’ environmental impact, Tesla’s future looks bright. As the company continues to innovate and scale its production, its mass flux will likely grow, cementing its position as a global transition to sustainable energy leader.

For now, the idea of Tesla moving 4 million tons of goods yearly is a powerful reminder of how far the company has come and how much more it can achieve in the future.

Tech enthusiast and digital expert, Techo Wise is the driving force behind techowise.com. With years of experience in viral trends and cutting-edge software tools, Techo Wise delivers insightful content that keeps readers updated on the latest in technology, software solutions, and trending digital innovations.